Gaskets Supplier and Exporter in UAE

Gaskets are essential components used to create a tight seal between two or more mating surfaces, preventing leakage of fluids or gases in a wide range of industrial applications. Here's a concise overview of gaskets:

- Function: Gaskets serve to fill the irregularities or imperfections between mating surfaces, thereby preventing the escape of fluids or gases under compression. They help maintain pressure, prevent leaks, and ensure the integrity of sealed joints in machinery, pipelines, engines, and other equipment.

- Materials: Gaskets can be made from various materials, each chosen based on factors such as temperature, pressure, chemical compatibility, and application requirements. Common materials include rubber (e.g., Nitrile, EPDM), graphite, PTFE (Teflon), metal (e.g., stainless steel, copper), and composite materials.

- Types: Gaskets come in different types to suit specific applications and conditions:

- Metallic Gaskets: These include spiral wound, ring joint, and Kammprofile gaskets, often used in high-pressure and high-temperature applications.

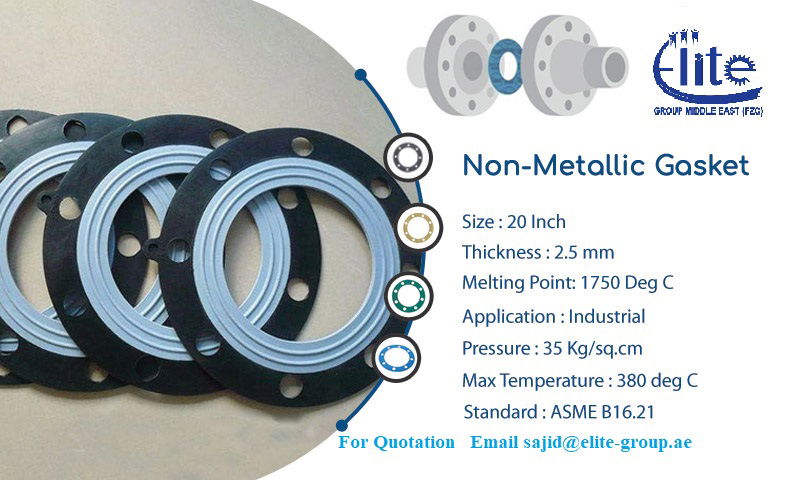

- Non-Metallic Gaskets: Such as rubber, PTFE, and graphite gaskets, preferred for their flexibility, chemical resistance, and sealing properties.

- Semi-Metallic Gaskets: Combining characteristics of both metallic and non-metallic gaskets, these include spiral wound gaskets with graphite or PTFE filler.

- Applications: Gaskets find application across various industries, including oil and gas, petrochemicals, automotive, aerospace, marine, power generation, HVAC (heating, ventilation, and air conditioning), and manufacturing.

- Installation: Proper installation and torqueing of gaskets are crucial for effective sealing. This involves cleaning and preparing mating surfaces, ensuring correct alignment, applying appropriate sealants or adhesives if necessary, and tightening bolts or fasteners to the recommended torque specifications.

- Maintenance: Regular inspection and replacement of gaskets are essential to prevent leaks and ensure continued operational efficiency. Factors such as temperature fluctuations, chemical exposure, and mechanical stress can degrade gasket performance over time, necessitating periodic maintenance and replacement.

- Quality Assurance: When sourcing gaskets, it's important to consider factors such as material quality, compliance with industry standards (e.g., ASTM, ASME), certification (e.g., ISO certification), and supplier reputation to ensure reliable performance and compatibility with specific application requirements.

Overall, gaskets are indispensable components in industrial machinery and equipment, playing a critical role in maintaining operational integrity, safety, and efficiency by providing reliable sealing solutions in a wide range of applications.